…and work and turn again. And then flip. Work and turn is a press process where both sides of a sheet are printed using one plate or make-ready. In this case, I’m using this method to avoid handling tiny pieces of paper.

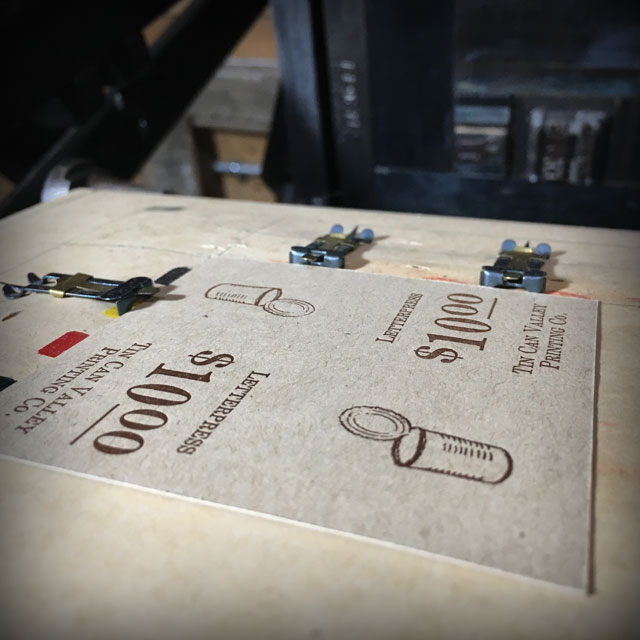

The finished size of these tags is 1.5″ square. If this job were done digitally or on an offset press, the image would be repeated as many times as could be fit on the largest sheet size available, then trimmed. And since this is hand-set type and the press-run is only a couple-hundred, I only needed to print this one-up.

But to save a step, I also set-up the backside image in the form, and printed the front and back in one operation. With the two images rotated 180 degrees, when the paper is flipped, so is the image on the reverse side.

But why stop there. I can also rotate the sheet 180 degrees, and print the same image once more, and then flip the sheet again, for four front-and-backs on one sheet.

On a job like this, all four passes can made on each piece, flipped and rotated, and then move on to the next piece; but I usually prefer to do the whole run of one operation. Less thinking that way. If the ink and stock combination is prone to offsetting or smudging, it’s best to let each side dry before running the next side.

You must be logged in to post a comment.